I've taken 1 blown rotary apart before, but this is the first one I've taken to bits when it might (or might not as the case may be...) go back together. Most of the engine threads I've seen have been taken from a more informed point of view, but as a newbie to all this it's hard to know what to look for and where the line between useable and just a bit too far gone lies. With this in mind I posted on the Exile forum where there's lots of guys with experience of doing rebuilds and now hopefully I can present a semi-informed autopsy of my 12a. I'd like to re-itterate that I've really new to this. All of the info in this thread is secondhand via pictures off the internet and the thanks to the Exile guys.

So first off, lets get some background. As far as I can tell this 12a is the original un-opened engine from my FB. According to the previous owner it was a daily driver from 84 to about 96, covering 72,000 miles. It then sat in a garage till my friend Ross bought it off eBay in 2010. After a good service it was then put back into daily driving by me from summer 2011 till spring 2012, when at 86,000 miles it started showing signs of damage.

The first signs of problems was that the hot starting ability started to deteriorate. It went from needing a few more turns of the starter to catch up to the point where it would be impossible to start when hot in about 3 weeks. After the first couple of weeks of hot start trouble I noticed a drop in fuel efficiency, a drop in power, more blue smoke and oil usage and a new vibration that just didn't feel right.

OK, so we've got an engine and the sun is shining.

So first thing was to take the sump off. The oil I took out of the engine had looked ok, if a bit thin, but the sludge left in the bottom of the sump has so many small metal particles in it, it looked like a nice gun metal metal flake paint! It also had some fairly sizeable chunks on metal.

Obviously the chunks of metal are a bad sign, as they are likely to be debris from broken engine parts, but apparently the sparkly bits as dramatic as they look. It would suggest parts have been wearing but its not the end of the world and maybe good strong running engines have been found to have similar sparkly bits in the bottom of the sump.

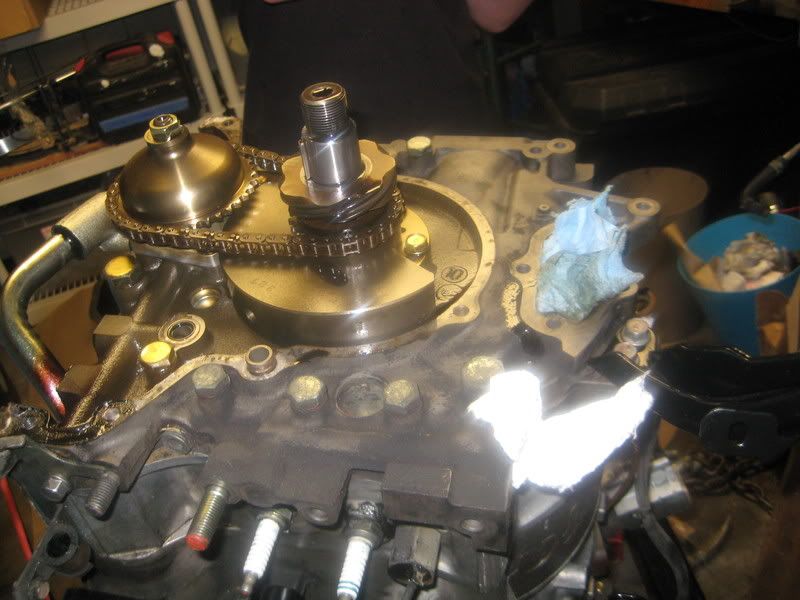

Next up was to remove the front pulley, front cover, front counter weight and oil pump assembly. I stupidly didn't take any photos of this in process. So here's a picture stolen from the internet to illustrate what the parts look like assembled.

Behind the front counter weight there is a thrust bearing. Mine didn't look good....

Here we can see where it's marked the counter weight from sitting off centre.

This could be my fault.... It's something I've heard before and now seems fairly confirmed, that if you take the front pulley off while the engine is in the car, or in the same position as if it were in the car then the bearing is no longer held tight and will drop. When you put the front pulley back on it crimps the bearing. I did take the pulley off with the engine in its normal orientation while I painted the engine.

A couple of guys on Exile suggested that this knackered bearing will mean that there will be excessive end float on the crank, which will lead to accelerated side seal and oil control seal wear and ultimately engine death. I've read that the best way to prevent this if you must take the pulley off is to stand the engine with the crank vertically (flywheel down).

Next post, lets open the short block.