C160SFG - 1986 Series 3

-

biznatch

- VIP User

- Posts: 346

- Joined: Mon Aug 26, 2013 3:03 pm

- Location: Hornchurch, Essex

- Been thanked: 1 time

Re: 1986 Series 3 Elford Turbo

Looks fantastic Ian and it's reliability is a testament to the work you have put into it

- ian65

- Admin

- Posts: 6402

- Joined: Wed Mar 30, 2011 12:11 am

- Has thanked: 232 times

- Been thanked: 276 times

Re: 1986 Series 3 Elford Turbo

thanks gents..... it ran really well today, that's probably the biggest distance I've been in it since last years RetroRides Gathering and it performed really well.... temperature rock solid and no nasty noises etc.

It's currently running the 12a out of Keiths TWR that I've installed his Elford setup onto so it's good to know that this turbo'd engine is running good and can just drop straight back into the TWR in the Autumn and should be just plug and play in that car.

It was nice giving it a blast in the sunshine today.

The wheels were diamond cut Pete as the original finish.

It's currently running the 12a out of Keiths TWR that I've installed his Elford setup onto so it's good to know that this turbo'd engine is running good and can just drop straight back into the TWR in the Autumn and should be just plug and play in that car.

It was nice giving it a blast in the sunshine today.

The wheels were diamond cut Pete as the original finish.

1999 Jaguar XJR V8 Supercharged

1992 Peugeot 205 1.9 GTI

2003 Mercedes SLK 200 Kompressor

- ian65

- Admin

- Posts: 6402

- Joined: Wed Mar 30, 2011 12:11 am

- Has thanked: 232 times

- Been thanked: 276 times

Re: 1986 Series 3 Elford Turbo

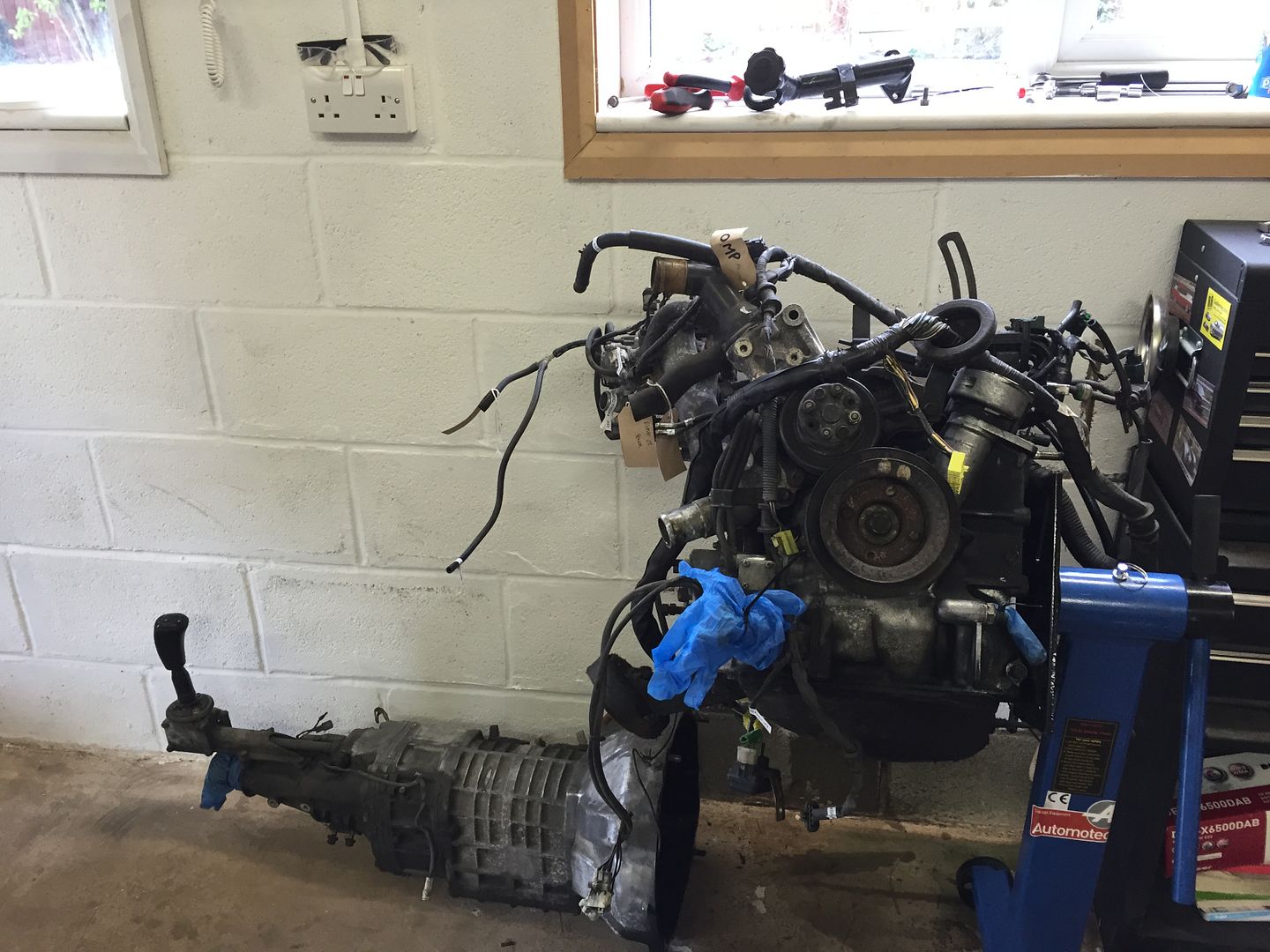

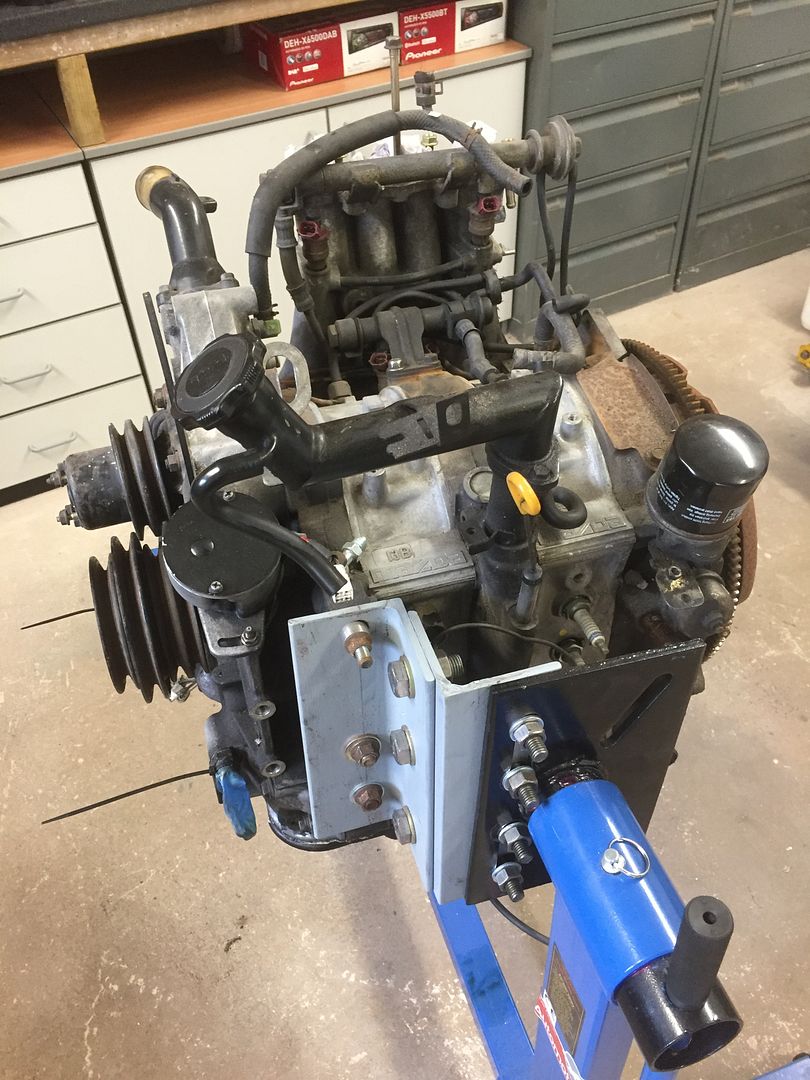

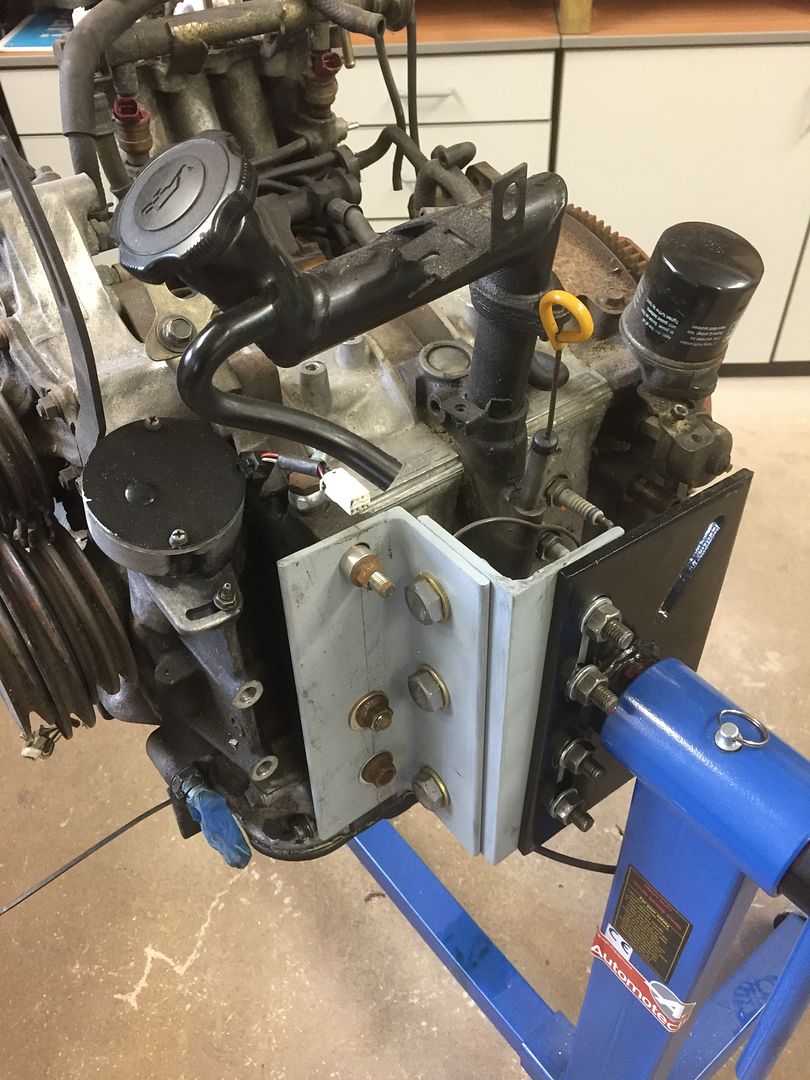

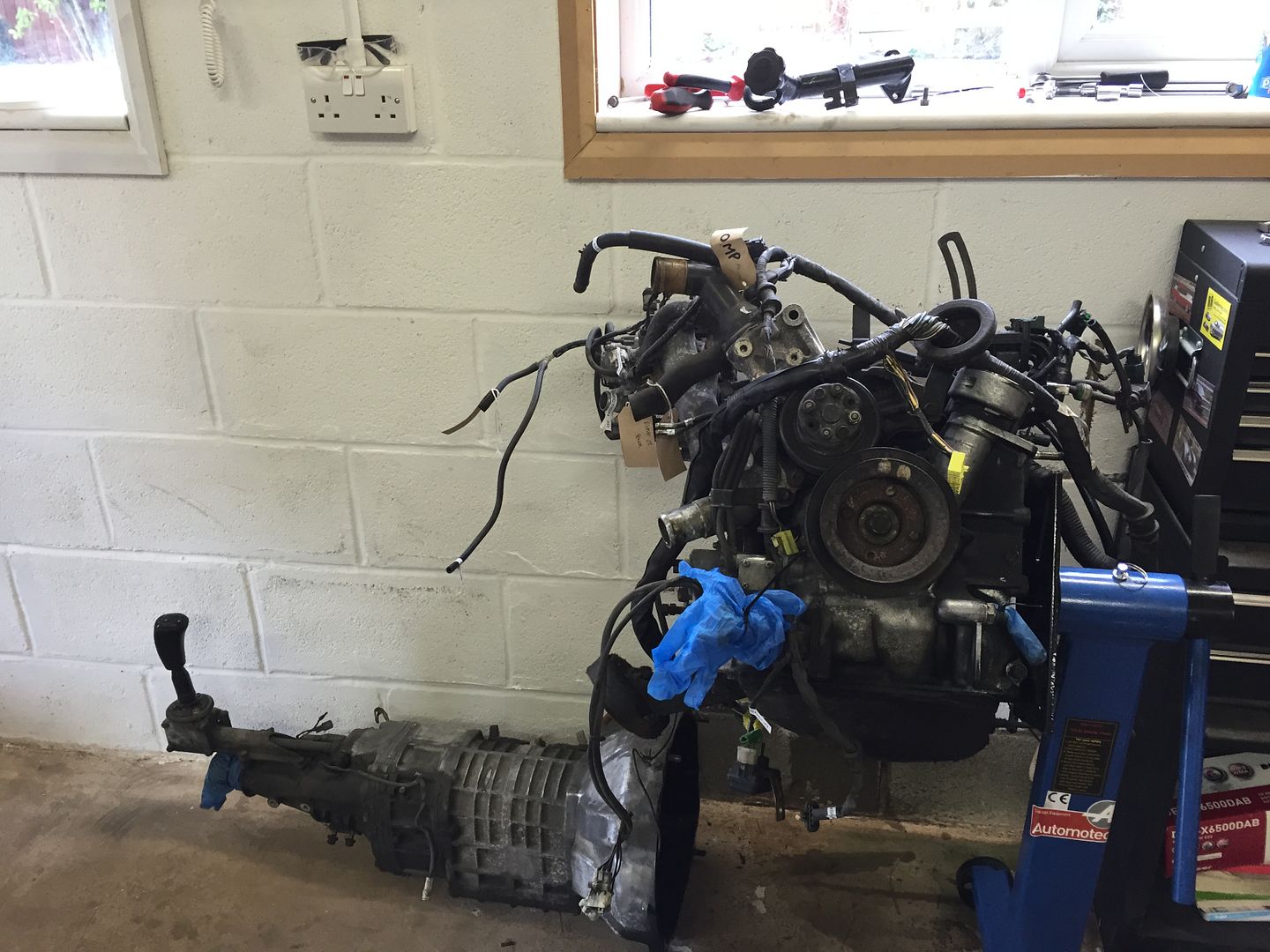

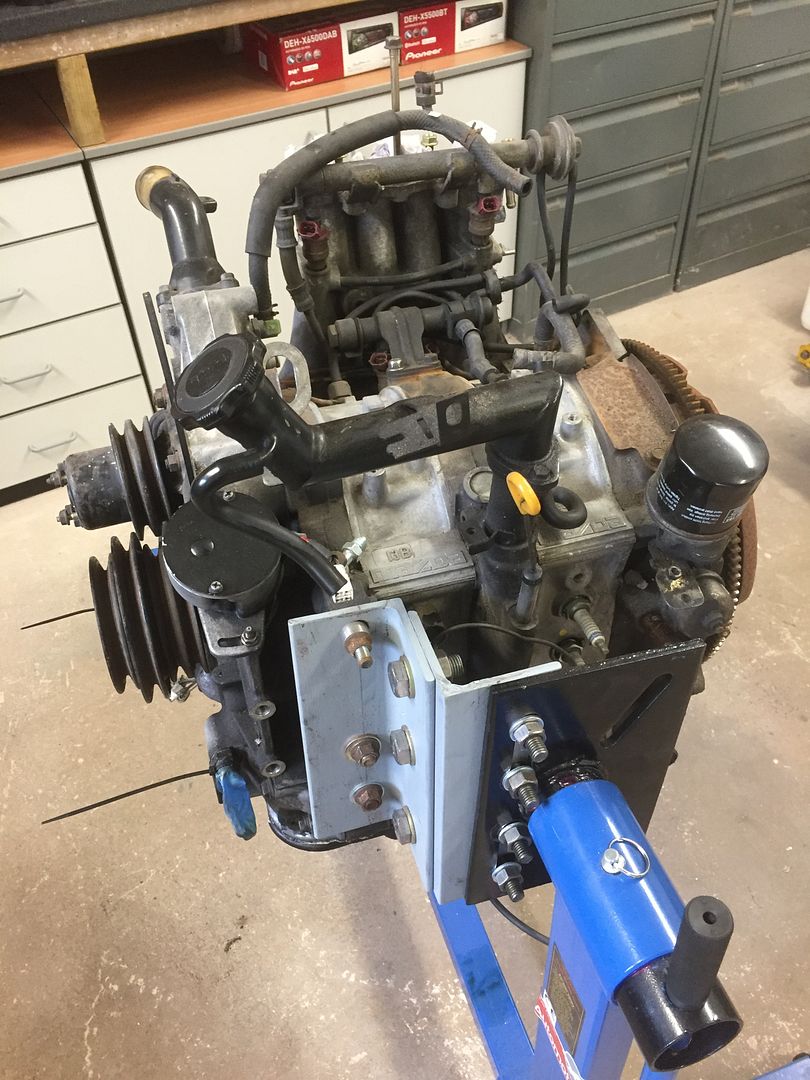

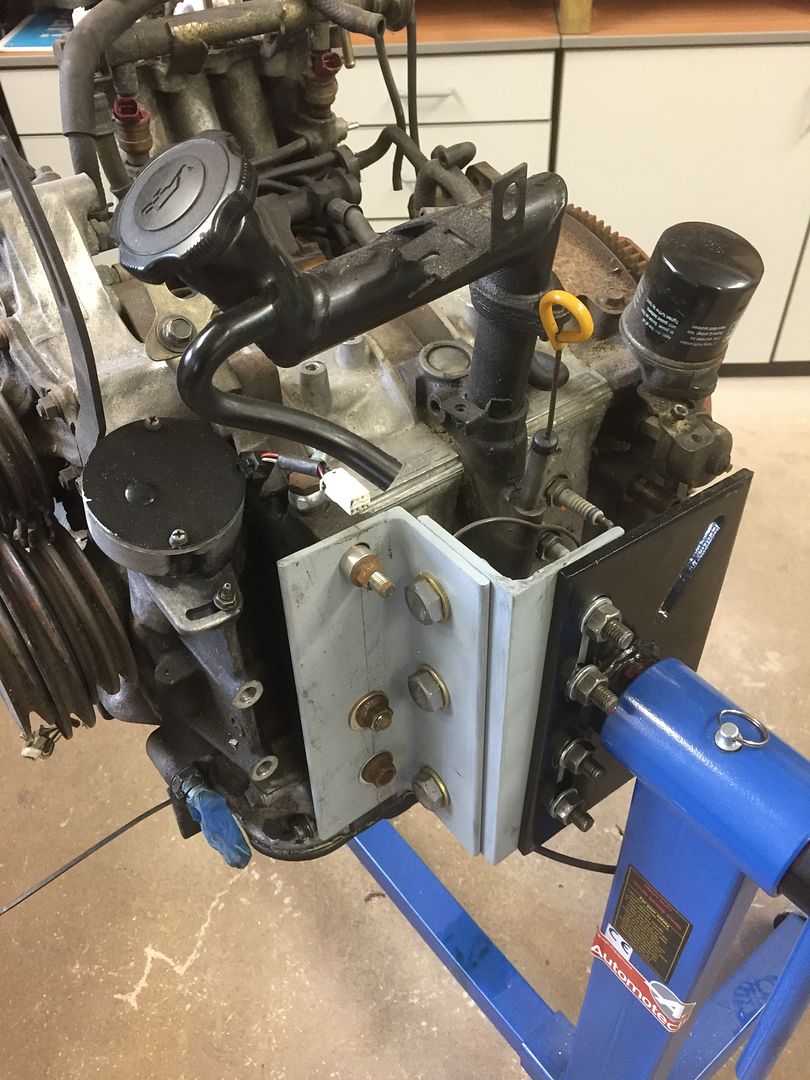

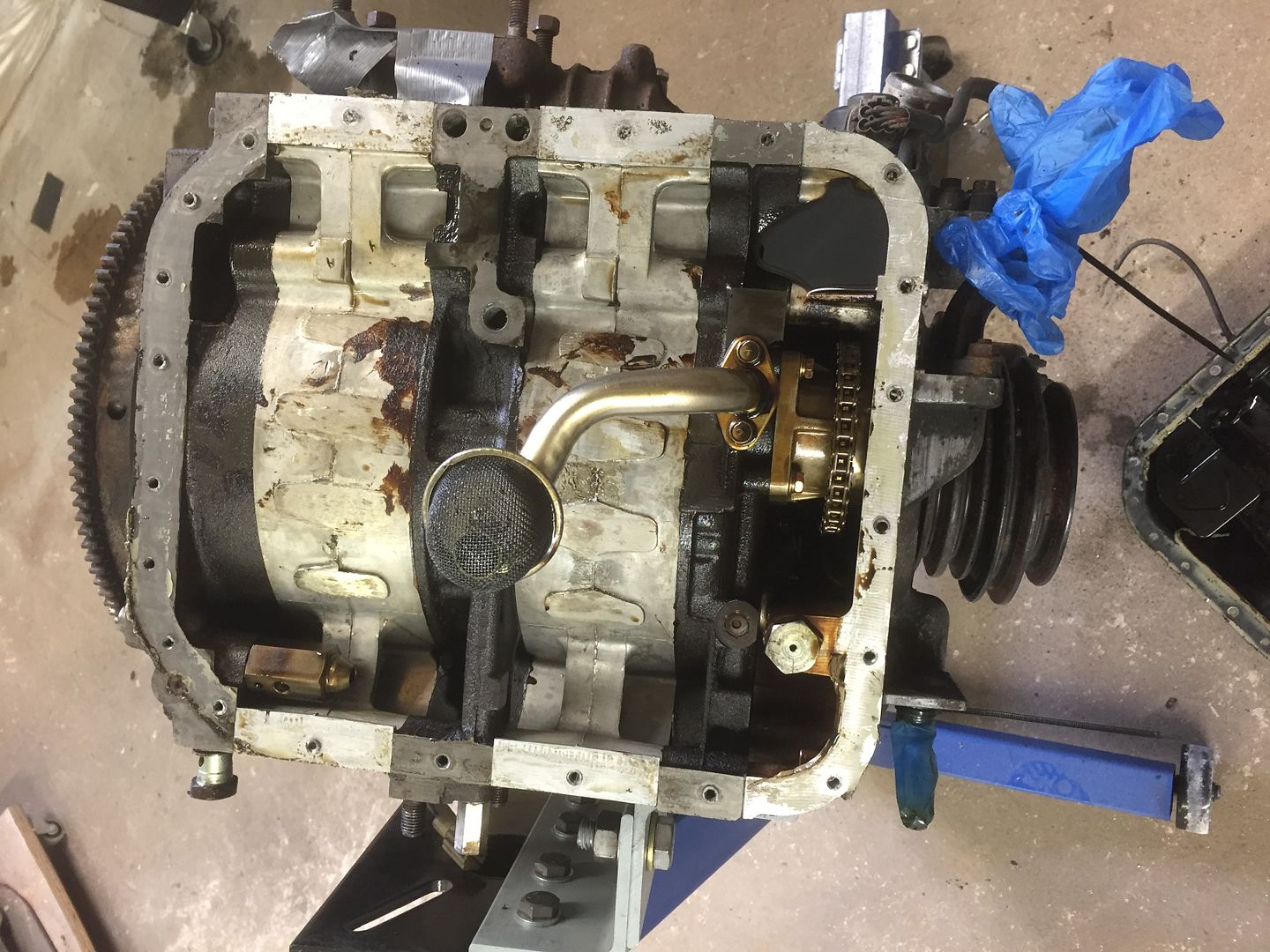

Last year I bought an engine stand to help me work on this TII engine..... the stand was a bargain at only £32 new from Automotec, the place I got my 2 post lift and engine hoist from and the quality is spot on.... mounting a rotary a bit more of a challenge though.

I wanted to side mount the engine and Pineapple in the US make an adapter plate specifically to mount a rotary engine...

without the adapter plate the engine isn't centered on the stand and is impossible to spin over safely...

the adapter shifts the centre of gravity to enable the stand to spin the engine block over.

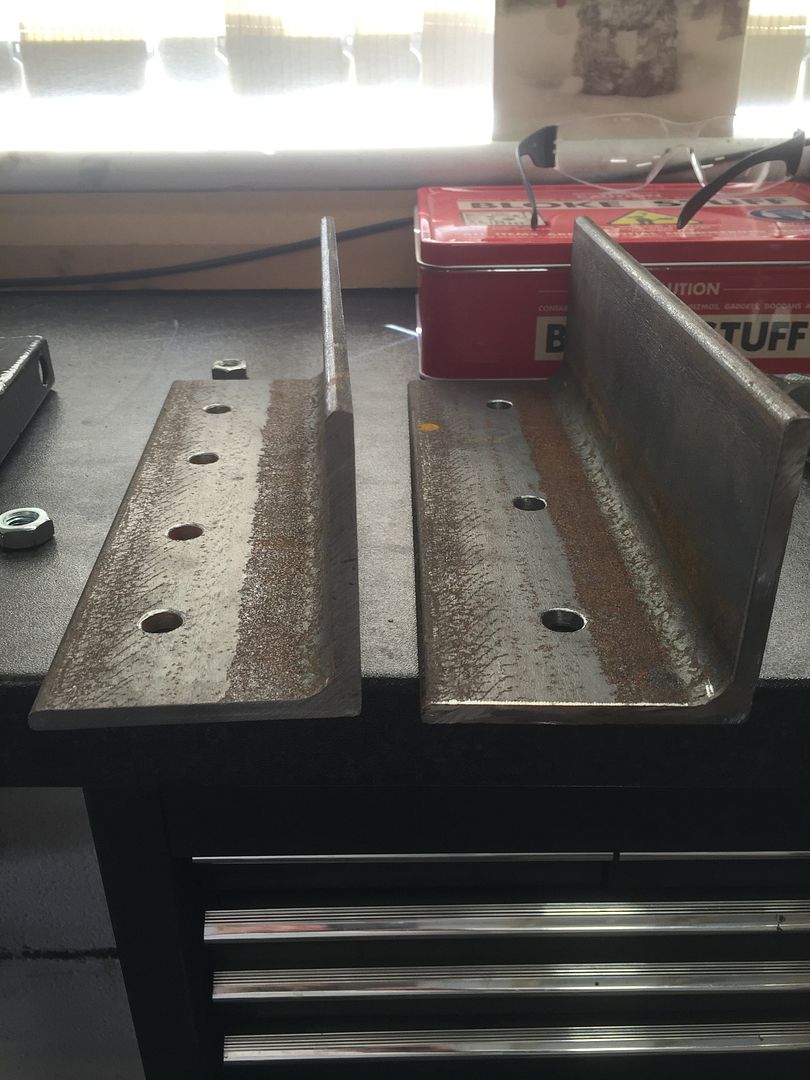

Now, the Pineapple item is a nice looking thing and I would like one very much..... but, they weigh loads and by the time I'd paid the purchase price, shipping, duty, vat, and anyone else who decided to have a cut, I couldn't justify the cost so decided to set to work in the mancave and cunningly fashion my own.

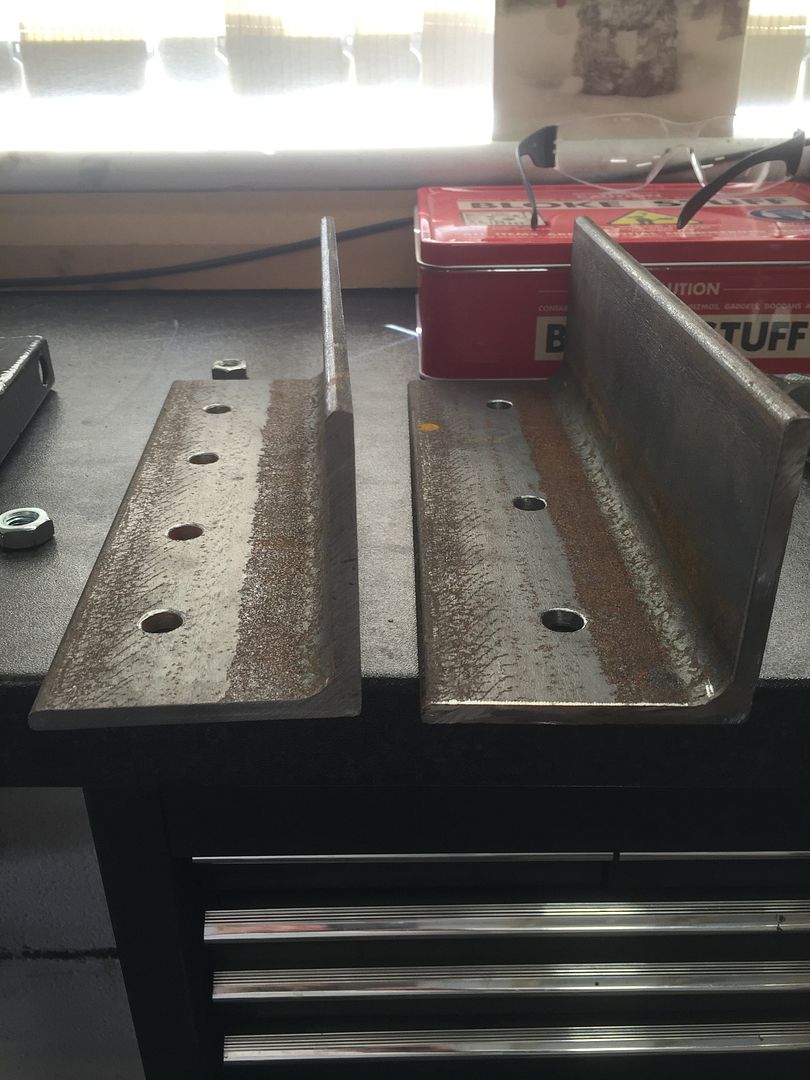

I bought a 600mm long piece of mild steel angle 75 x 75 x 6mm, cut it in half and drilled some holes in it...

then gave them a coat of zinc primer and bolted them together with M16 Bolts. It now fits both the stand and the engine and works a treat...

makes spinning the engine over a piece of cake...

I can now get on with sorting this engine to go into my FB.... it'll need to come off the stand to change the front cover but it's only 3 bolts to undo it.... happy days

I wanted to side mount the engine and Pineapple in the US make an adapter plate specifically to mount a rotary engine...

without the adapter plate the engine isn't centered on the stand and is impossible to spin over safely...

the adapter shifts the centre of gravity to enable the stand to spin the engine block over.

Now, the Pineapple item is a nice looking thing and I would like one very much..... but, they weigh loads and by the time I'd paid the purchase price, shipping, duty, vat, and anyone else who decided to have a cut, I couldn't justify the cost so decided to set to work in the mancave and cunningly fashion my own.

I bought a 600mm long piece of mild steel angle 75 x 75 x 6mm, cut it in half and drilled some holes in it...

then gave them a coat of zinc primer and bolted them together with M16 Bolts. It now fits both the stand and the engine and works a treat...

makes spinning the engine over a piece of cake...

I can now get on with sorting this engine to go into my FB.... it'll need to come off the stand to change the front cover but it's only 3 bolts to undo it.... happy days

1999 Jaguar XJR V8 Supercharged

1992 Peugeot 205 1.9 GTI

2003 Mercedes SLK 200 Kompressor

- ian65

- Admin

- Posts: 6402

- Joined: Wed Mar 30, 2011 12:11 am

- Has thanked: 232 times

- Been thanked: 276 times

Re: 1986 Series 3 Elford Turbo

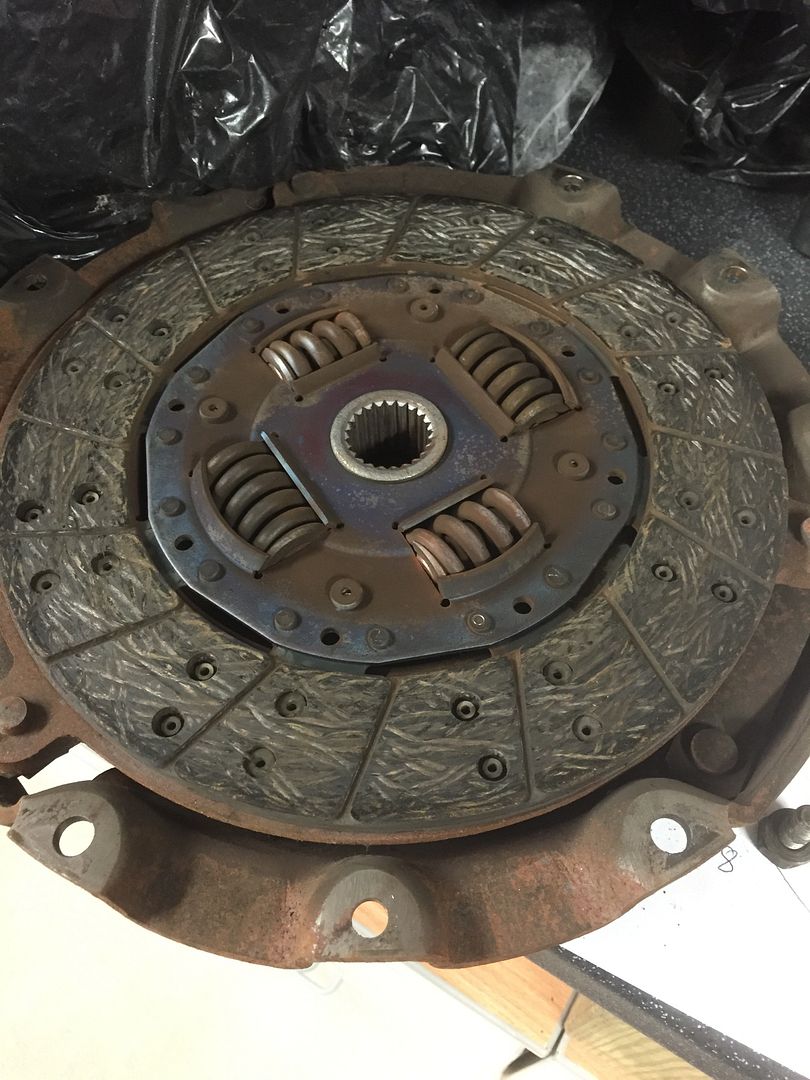

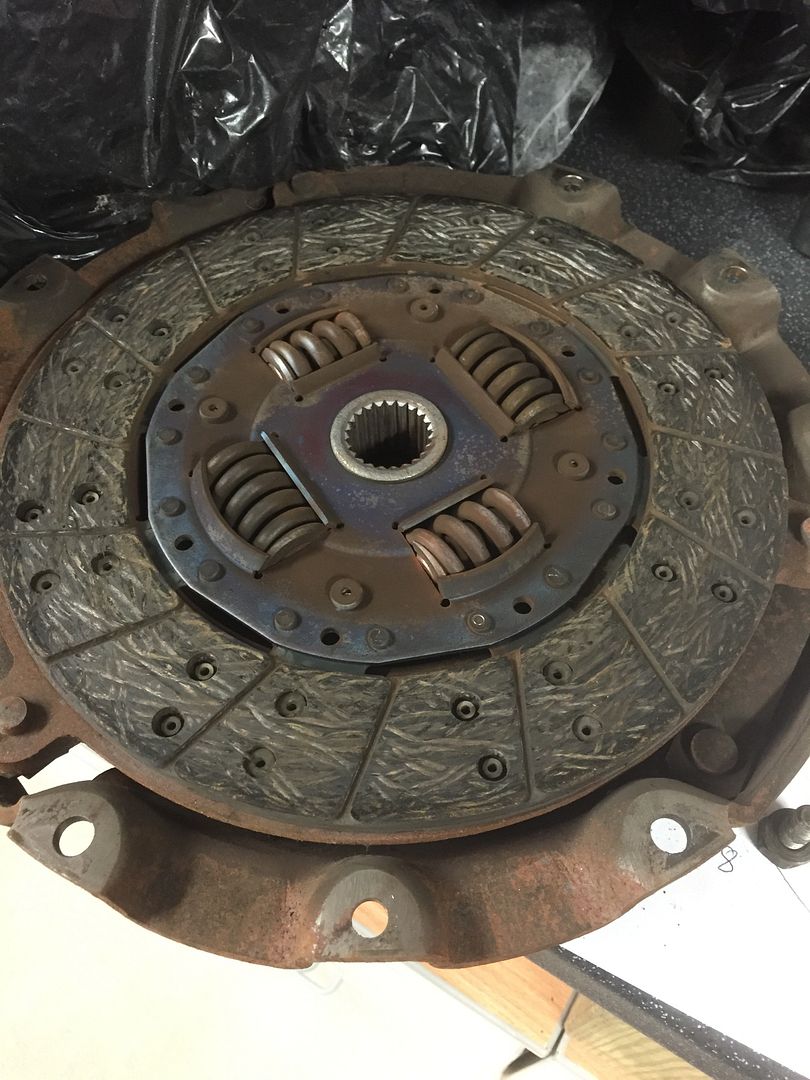

making use of my new super twizzler, I took the clutch off to check it and the fly..... the clutch pressure plate has lots of surface rust...

but is otherwise in excellent condition and doesn't look as if it's had much use. The clutch plate also looks nearly new...

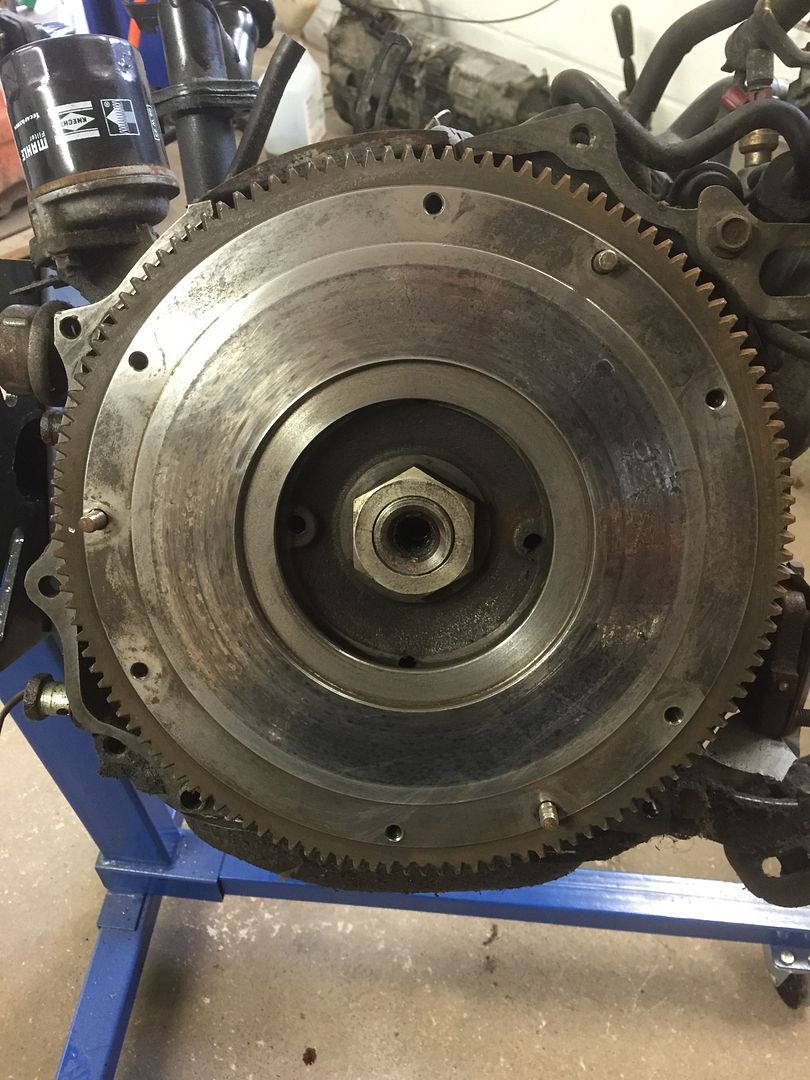

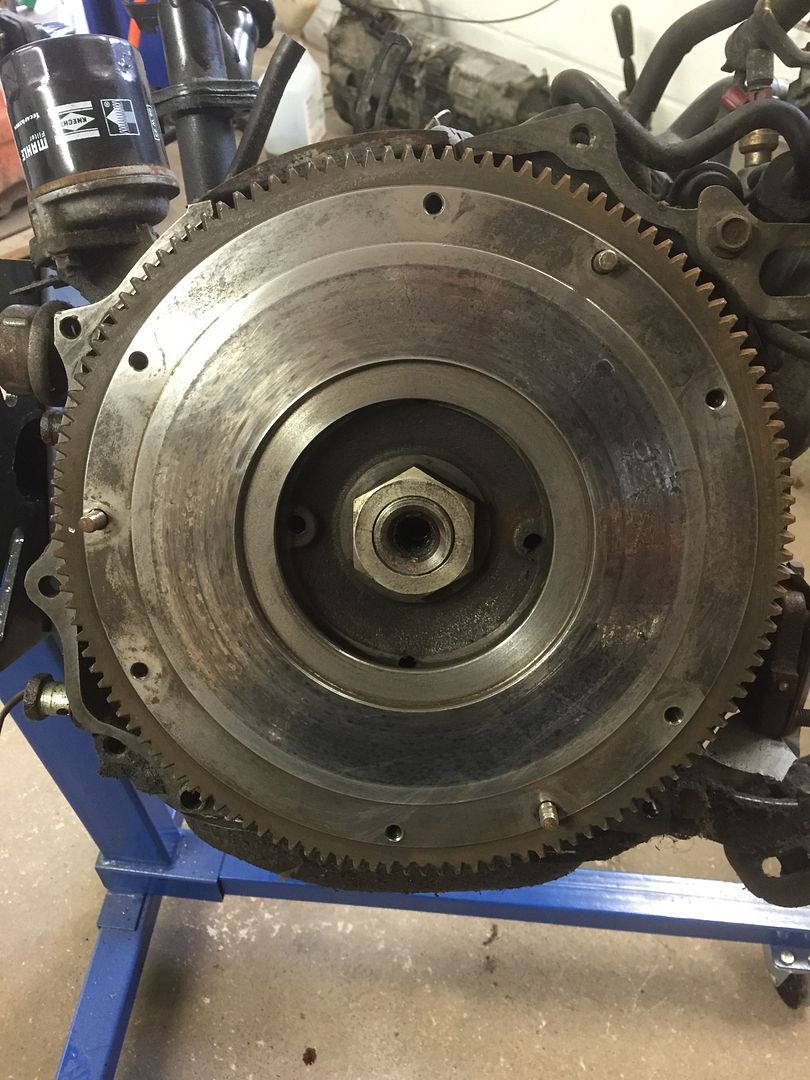

and the surface of the fly is also fine...

I don't know what to do about the clutch I don't really want to buy a new one when this one looks hardly used but what to do about the rust.... could i just rub it down and spray it with cold galvanising or should I just bin it and buy a new pressure plate? Any thoughts?

I don't really want to buy a new one when this one looks hardly used but what to do about the rust.... could i just rub it down and spray it with cold galvanising or should I just bin it and buy a new pressure plate? Any thoughts?

.

but is otherwise in excellent condition and doesn't look as if it's had much use. The clutch plate also looks nearly new...

and the surface of the fly is also fine...

I don't know what to do about the clutch

.

1999 Jaguar XJR V8 Supercharged

1992 Peugeot 205 1.9 GTI

2003 Mercedes SLK 200 Kompressor

- ian65

- Admin

- Posts: 6402

- Joined: Wed Mar 30, 2011 12:11 am

- Has thanked: 232 times

- Been thanked: 276 times

Re: 1986 Series 3 Elford Turbo

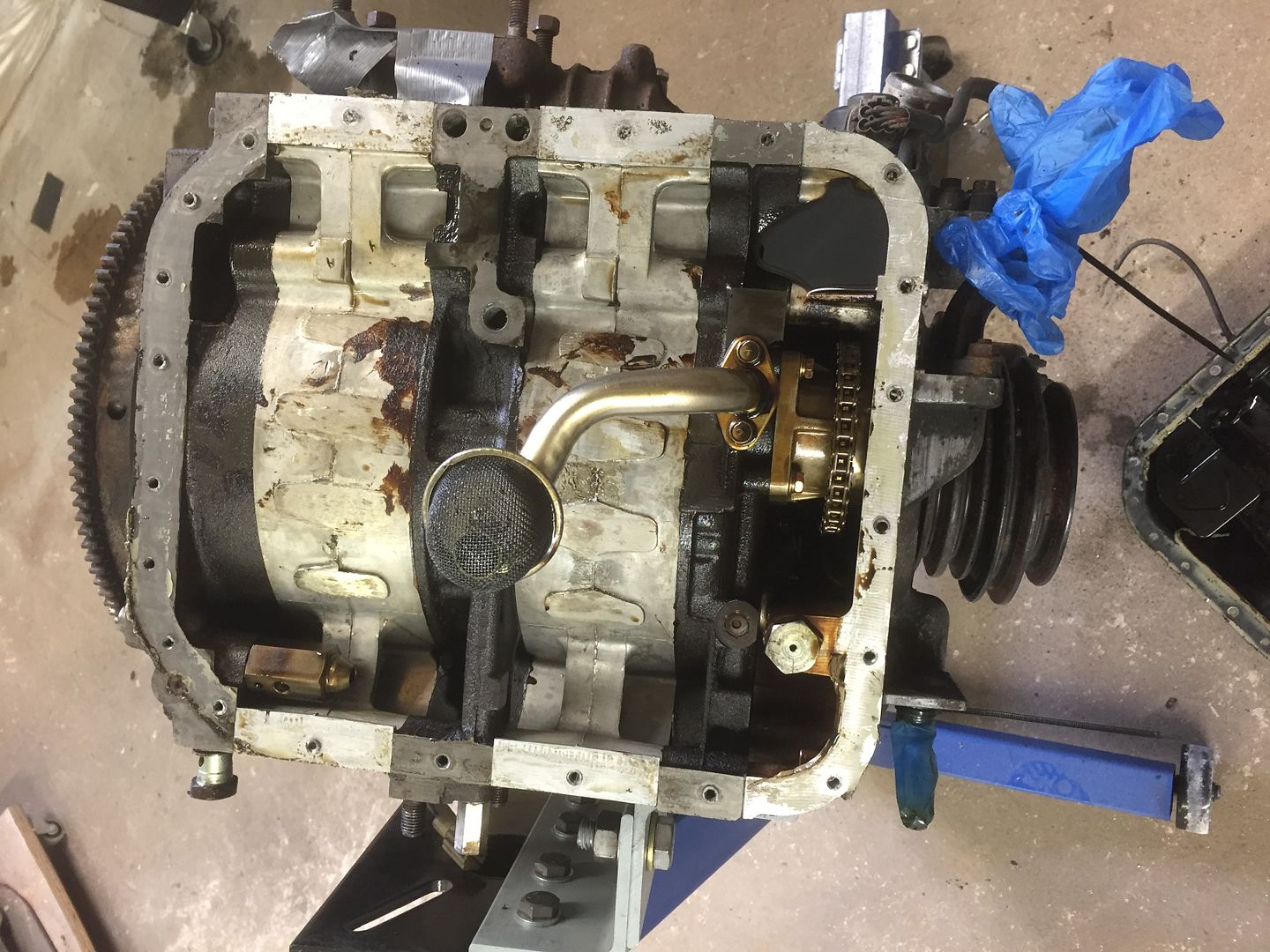

Next to go was the engine mount and the sump...

followed by the electric oil metering pump...

Pip has got a new GSL_SE sump on order for me from the States and I've already got the front cover so I need to get a front cover gasket now and I can swap the covers.

.

followed by the electric oil metering pump...

Pip has got a new GSL_SE sump on order for me from the States and I've already got the front cover so I need to get a front cover gasket now and I can swap the covers.

.

1999 Jaguar XJR V8 Supercharged

1992 Peugeot 205 1.9 GTI

2003 Mercedes SLK 200 Kompressor

- DKWW2000

- VIP User

- Posts: 1626

- Joined: Sun Jul 06, 2014 10:16 pm

- Location: English Riviera - South Devon

- Has thanked: 125 times

- Been thanked: 118 times

Re: 1986 Series 3 Elford Turbo

Great job on the adapter bracket.ian65 wrote:

I don't know what to do about the clutchI don't really want to buy a new one when this one looks hardly used but what to do about the rust.... could i just rub it down and spray it with cold galvanising or should I just bin it and buy a new pressure plate? Any thoughts?

.

Regarding the surface rust , I would remove rust with a wire brush & then apply some of this stuff,

http://www.ebay.co.uk/itm/HAMMERITE-KUR ... SwxH1T9MqV

Works wonders on Calipers/Drums & any other surface rust, goes on like milk but turns black & forms a hard surface.

I use it on all sorts of external parts & farm machinery etc.

RX7 FB S3 - RX7 FC TII Vert

Rotaries Previously Owned:-

2 x NSU Ro 80s - 2 x S2 RX7s - Suzuki RE 5 - DKW(Hercules) W2000 - Norton (Krauser) Commander

Rotaries Previously Owned:-

2 x NSU Ro 80s - 2 x S2 RX7s - Suzuki RE 5 - DKW(Hercules) W2000 - Norton (Krauser) Commander

- ian65

- Admin

- Posts: 6402

- Joined: Wed Mar 30, 2011 12:11 am

- Has thanked: 232 times

- Been thanked: 276 times

Re: 1986 Series 3 Elford Turbo

good idea  I might have some of that in the cupboard

I might have some of that in the cupboard

1999 Jaguar XJR V8 Supercharged

1992 Peugeot 205 1.9 GTI

2003 Mercedes SLK 200 Kompressor

-

TOOL

- VIP User

- Posts: 2598

- Joined: Thu Sep 01, 2011 10:30 am

- Location: Switzerland

- Been thanked: 10 times

Re: 1986 Series 3 Elford Turbo

Just rub the flywheel and pressure plate with a but of emery cloth.ian65 wrote:could i just rub it down and spray it with cold galvanising or should I just bin it and buy a new pressure plate? Any thoughts?

Surface rust will never be seen in the bell housing and won't affect performance.

If it fails later it'll be an easy job with a 2 post.

Check to see if it's an up rated unit too. What's the thickness of the diaphragm fingers?

Back in the UK for the summer, maybe longer......

- ian65

- Admin

- Posts: 6402

- Joined: Wed Mar 30, 2011 12:11 am

- Has thanked: 232 times

- Been thanked: 276 times

Re: 1986 Series 3 Elford Turbo

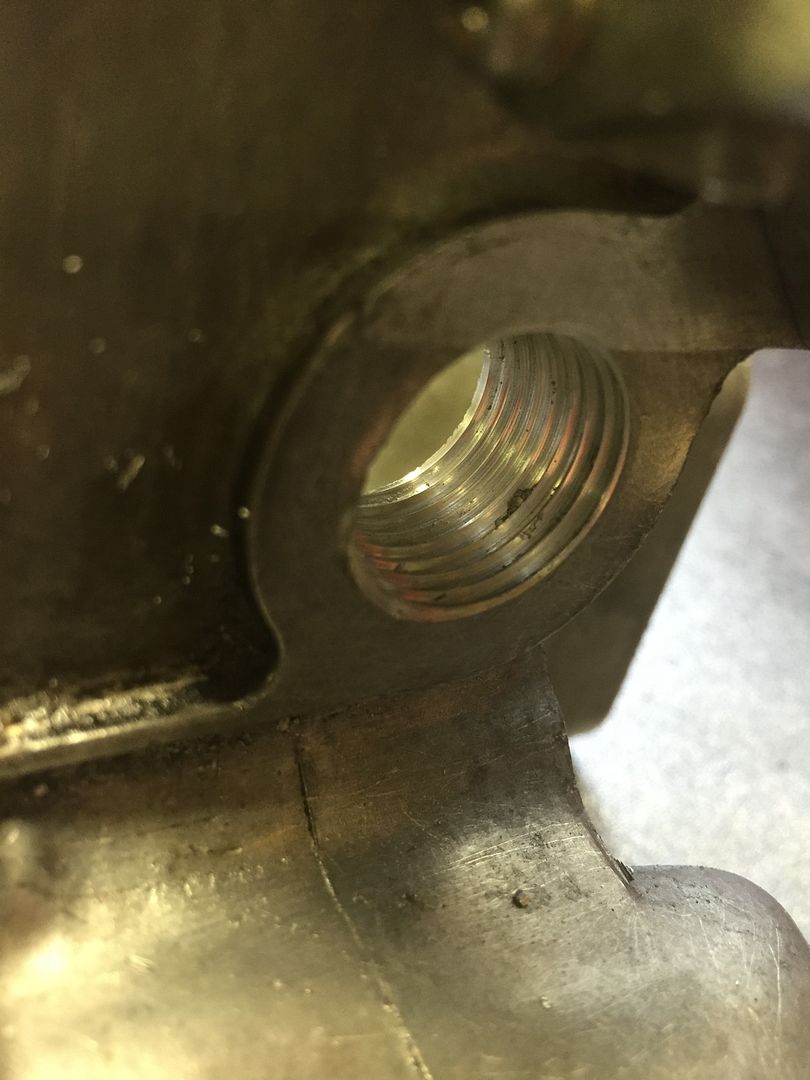

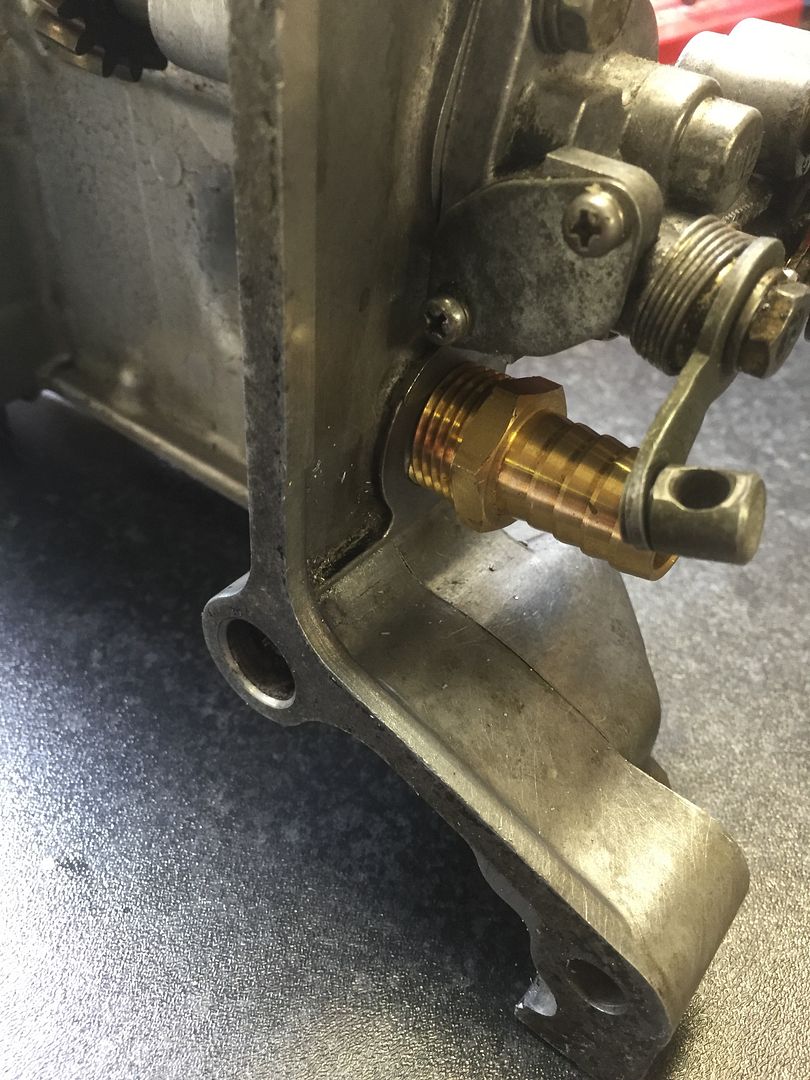

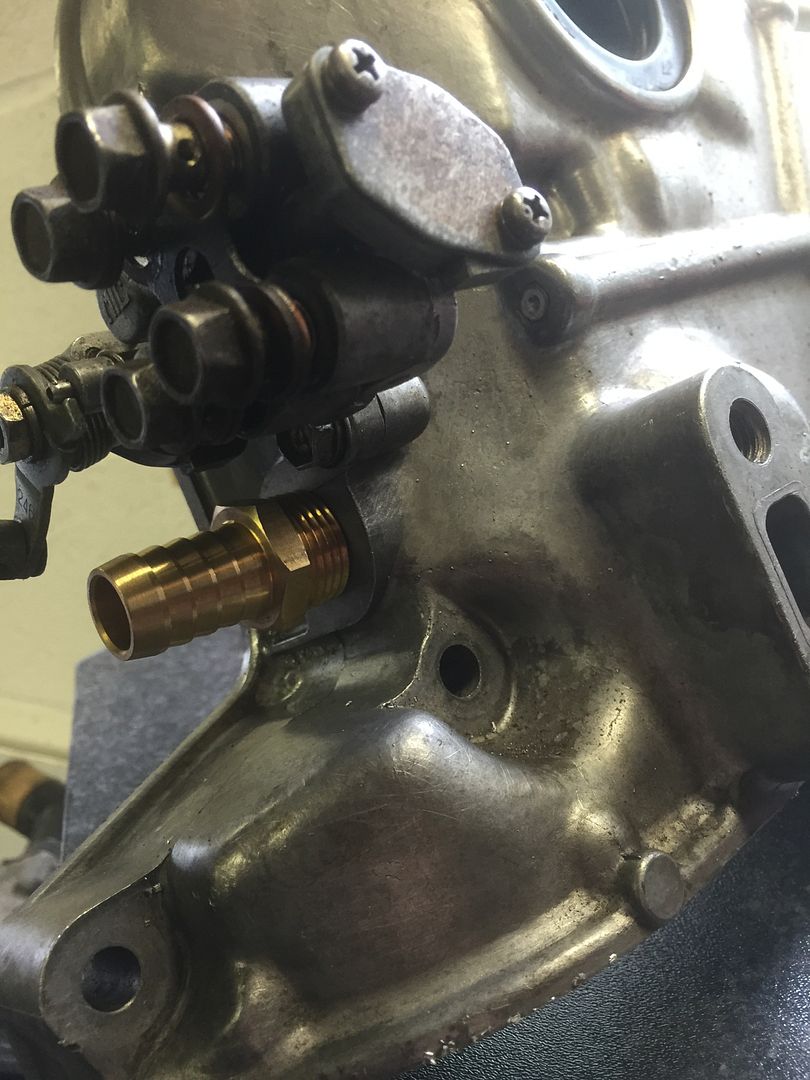

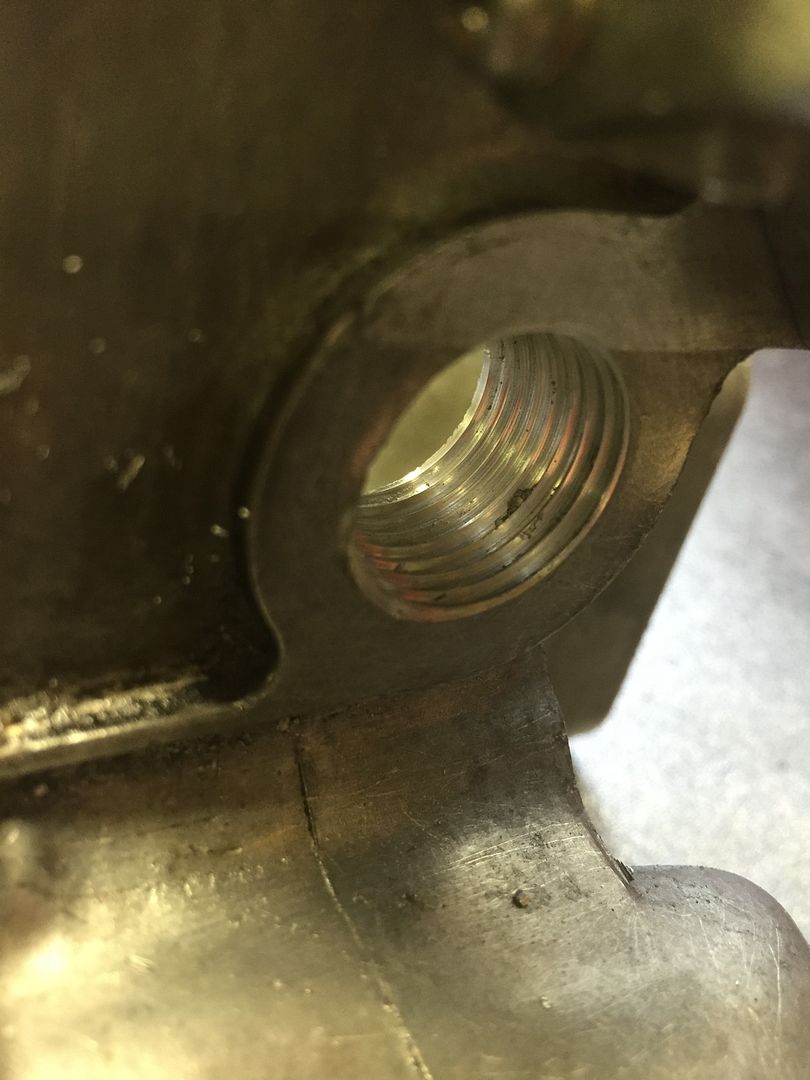

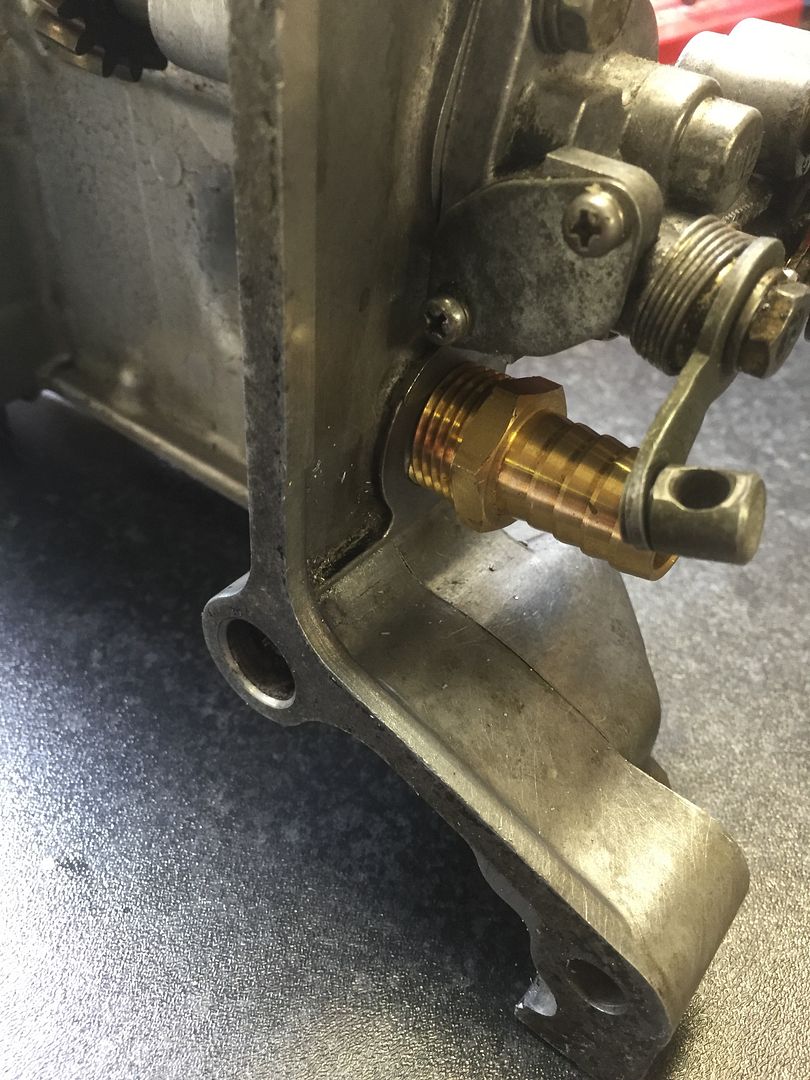

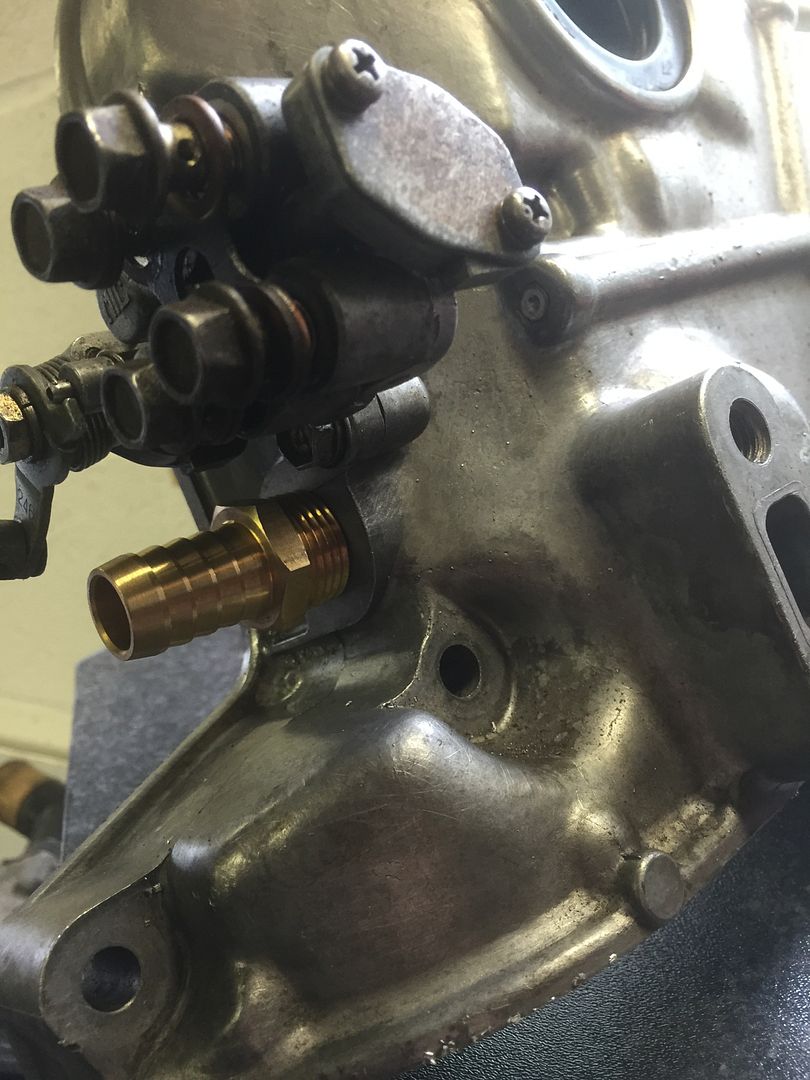

Drilled and tapped my front cover to take the oil return line from the turbo...

I bought a 18mm threaded brass union and a tap and drill bit to suit...

the main reasons i wanted a GSL-SE front cover, apart from it's capability to mount a S4 OMP, was that the area directly under the pump lends itself to threading in an oil return, the alloy around the pre-formed hole being very thick and strong...

I drilled it out and ran the tap through it...

and the oil return union fits a treat... just need a copper washer now before I tighten it all the way up...

.

I bought a 18mm threaded brass union and a tap and drill bit to suit...

the main reasons i wanted a GSL-SE front cover, apart from it's capability to mount a S4 OMP, was that the area directly under the pump lends itself to threading in an oil return, the alloy around the pre-formed hole being very thick and strong...

I drilled it out and ran the tap through it...

and the oil return union fits a treat... just need a copper washer now before I tighten it all the way up...

.

1999 Jaguar XJR V8 Supercharged

1992 Peugeot 205 1.9 GTI

2003 Mercedes SLK 200 Kompressor

- ian65

- Admin

- Posts: 6402

- Joined: Wed Mar 30, 2011 12:11 am

- Has thanked: 232 times

- Been thanked: 276 times

Re: 1986 Series 3 Elford Turbo

Retrorides gathering here I come...

1999 Jaguar XJR V8 Supercharged

1992 Peugeot 205 1.9 GTI

2003 Mercedes SLK 200 Kompressor