Re: Lucky's Series 3

Posted: Thu Apr 19, 2012 5:06 pm

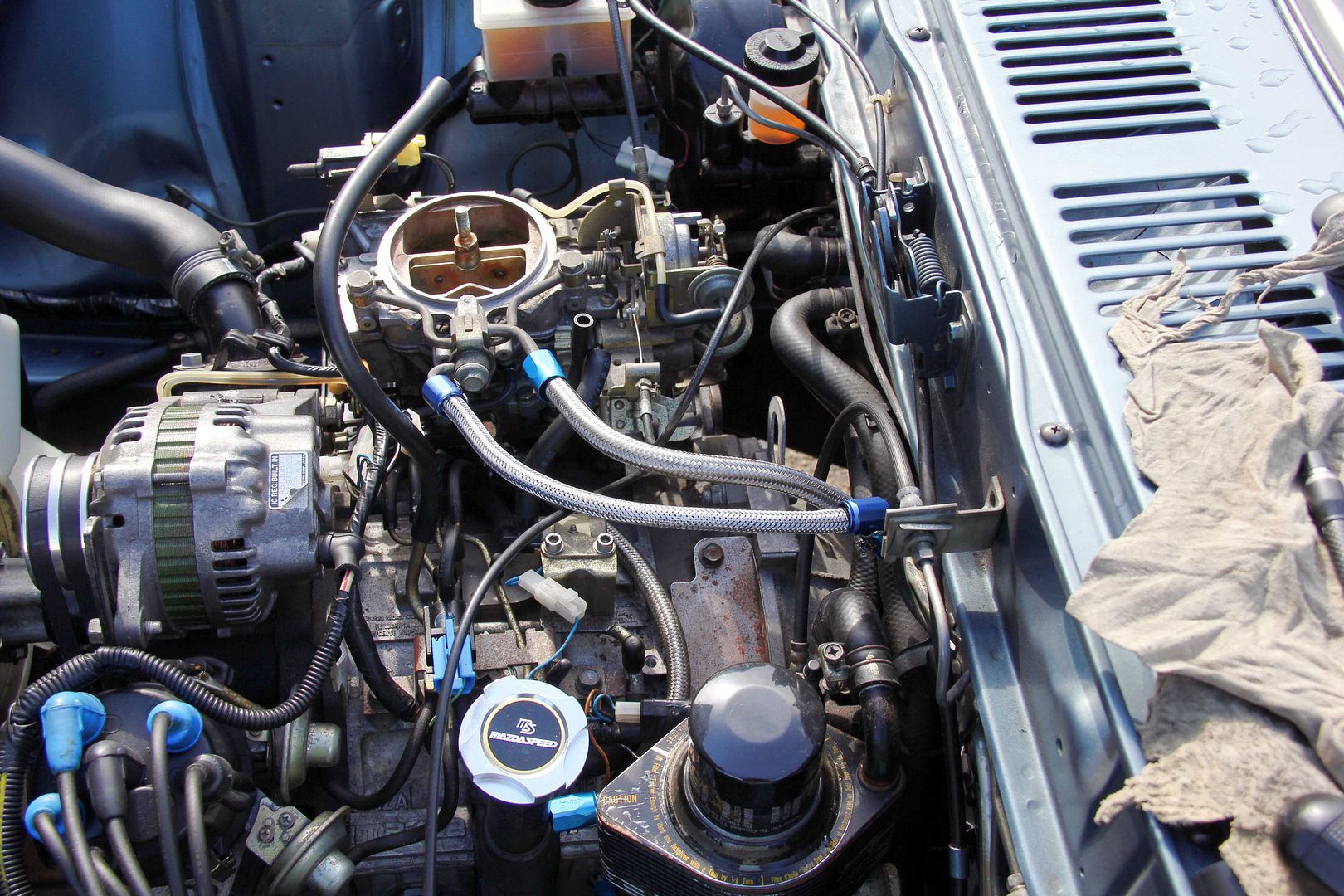

Bit more progress today. Had to do stuff in the garage as it kept pissing down every time I stuck my snout outside, so I couldn't get on with swapping the perished fuel hose like I wanted to  Annoying, but it hasn't caught fire yet, I guess a few more days won't hurt it. Hopefully that wasn't tempting fate

Annoying, but it hasn't caught fire yet, I guess a few more days won't hurt it. Hopefully that wasn't tempting fate

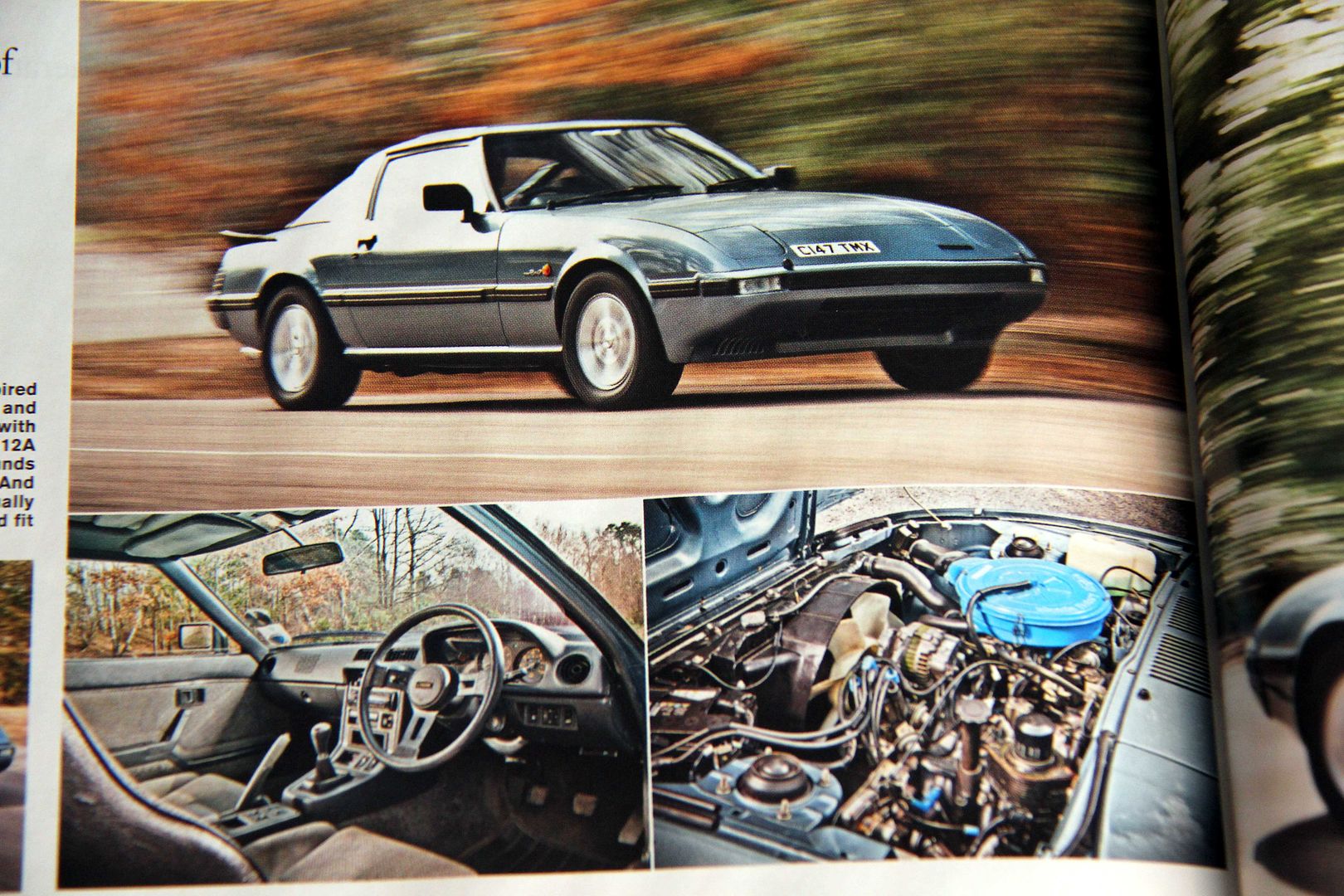

Anyway, side repeaters. I've become something of an authority on side repeaters in my quest to lose the giant tango-hued things :x Lets face it, nothing tango-coloured ought be suffered to come near an RX-7 Trouble is, apart from UK FBs and FCs, no other car on the planet seems to have the same side repeaters, and I couldn't find anyone doing clear or smoked replacements. So the only option was to replace them with something else. Trouble with that is, once you remove the horrid stockers, you're left with this;

Trouble is, apart from UK FBs and FCs, no other car on the planet seems to have the same side repeaters, and I couldn't find anyone doing clear or smoked replacements. So the only option was to replace them with something else. Trouble with that is, once you remove the horrid stockers, you're left with this;

Which is hardly condusive to easy replacement, even if you could find a mounting that fitted in the cut-out you're left with the two screw holes. Plating and painting would be one option, but not for me; too overkill and as always, too hard to put back to stock if necessary. So, let me take you on a little journey into my world of borderline autistic levels of OCD and mania.....

First thing was to source the smallest side repeaters I could find (round ones anyway, old Ford 'scorts had little square ones, but that'd look pony). Came up with some Fiat Seicento ones. Only firm I could find doing clear ones was in Germany, so they're EU-approved, TUV approved and probably built to higher standard than anything else on the car lol. The ones on Cinquecentos are smaller, really tiny, but no-one does clear ones. Guess not many people Max-up Cinqs So we have this to work with;

So we have this to work with;

Obviosuly, a plate is now needed to mount them and cover the wreckage Mazda saw fit to drill through the wing. I was gonna do it in alloy cos it's easy to work with and light, but would look cack in sliver, so I'd have to paint it and then it'd scratch... and look cack. Eventually settled on carbon fibre cos it's also easy to work, light, looks cool, etc. Genuine stuff, not Farbon, either

Can you tell what it is yet lol. The shape was an obvious choice, really. Sorta homage to the Spirit R badge stylee and all that. Requires a steady hand cutting out...

Next thing was to relieve the lenses a little. They almost fitted between the screw holes for the originals, but not quite. Bugger!

God knows what the home enthusiast did before Dremels, lol. Actually, I remember perfectly well what we did and it involved a hella lot of faffing around with hacksaws and files Still, a bit of Dremel action later...

Still, a bit of Dremel action later...

Then of course the German-supplied orange bulbs had to be sacked out in favour of nice chrome ones in order to avoid the fried-hegg look

Much better

Then in order to keep the wing waterproof and stop rust getting in behind, a gasket was needed. Now I had one plate made up it was easy to use as a template for everything else. A good quality rubber sheet 3mm thick made for perfect gasket material. Hey, everyone should have rubber sheets easy to hand

Then the final touches; a spot of countersinking and some silver enamel, just to add a bit of detail and make it look like these were designed to be there, not just a random-shaped lump of carbon glued to the wing

and some black on the screwheads to try and invisible-ise them and stop it getting too cluttered and busy

...and Boom!

rotor-shaped bespoke side repeaters that (hopefully) look much better than the horrid stock orange ones, and more importantly, maybe look like they were meant to be there all along

Maybe it seems a slightly obsessive length to go to over such a little thing, but in actual fact it only took an afternoon and a lot of it was measuring carefully a few times before cutting the first template out. After that, it was peasy. And I've got some carbon rotor side repeaters, and you haven't . So I win

. So I win

Anyway, side repeaters. I've become something of an authority on side repeaters in my quest to lose the giant tango-hued things :x Lets face it, nothing tango-coloured ought be suffered to come near an RX-7

Which is hardly condusive to easy replacement, even if you could find a mounting that fitted in the cut-out you're left with the two screw holes. Plating and painting would be one option, but not for me; too overkill and as always, too hard to put back to stock if necessary. So, let me take you on a little journey into my world of borderline autistic levels of OCD and mania.....

First thing was to source the smallest side repeaters I could find (round ones anyway, old Ford 'scorts had little square ones, but that'd look pony). Came up with some Fiat Seicento ones. Only firm I could find doing clear ones was in Germany, so they're EU-approved, TUV approved and probably built to higher standard than anything else on the car lol. The ones on Cinquecentos are smaller, really tiny, but no-one does clear ones. Guess not many people Max-up Cinqs

Obviosuly, a plate is now needed to mount them and cover the wreckage Mazda saw fit to drill through the wing. I was gonna do it in alloy cos it's easy to work with and light, but would look cack in sliver, so I'd have to paint it and then it'd scratch... and look cack. Eventually settled on carbon fibre cos it's also easy to work, light, looks cool, etc. Genuine stuff, not Farbon, either

Can you tell what it is yet lol. The shape was an obvious choice, really. Sorta homage to the Spirit R badge stylee and all that. Requires a steady hand cutting out...

Next thing was to relieve the lenses a little. They almost fitted between the screw holes for the originals, but not quite. Bugger!

God knows what the home enthusiast did before Dremels, lol. Actually, I remember perfectly well what we did and it involved a hella lot of faffing around with hacksaws and files

Then of course the German-supplied orange bulbs had to be sacked out in favour of nice chrome ones in order to avoid the fried-hegg look

Much better

Then in order to keep the wing waterproof and stop rust getting in behind, a gasket was needed. Now I had one plate made up it was easy to use as a template for everything else. A good quality rubber sheet 3mm thick made for perfect gasket material. Hey, everyone should have rubber sheets easy to hand

Then the final touches; a spot of countersinking and some silver enamel, just to add a bit of detail and make it look like these were designed to be there, not just a random-shaped lump of carbon glued to the wing

and some black on the screwheads to try and invisible-ise them and stop it getting too cluttered and busy

...and Boom!

rotor-shaped bespoke side repeaters that (hopefully) look much better than the horrid stock orange ones, and more importantly, maybe look like they were meant to be there all along

Maybe it seems a slightly obsessive length to go to over such a little thing, but in actual fact it only took an afternoon and a lot of it was measuring carefully a few times before cutting the first template out. After that, it was peasy. And I've got some carbon rotor side repeaters, and you haven't