Lucky wrote:Love spoon?

Hahaha ... I like your thinking there. It's flexible but rigid at the same time and kinda like the stuff you use

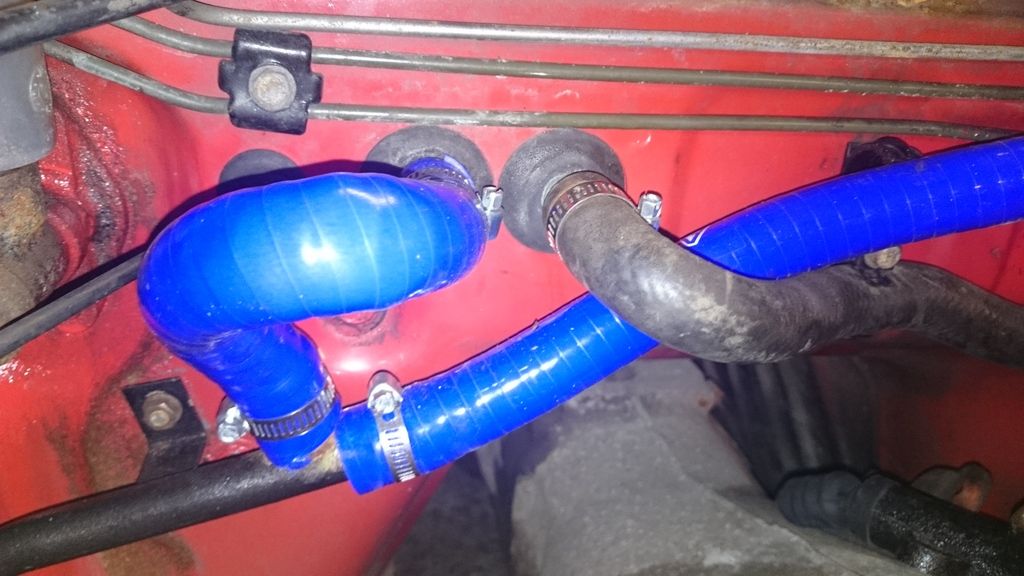

I'm a silicon hose virgin really. For instance, I've just discovered that I can get 120 and 180 degree bent sections as well

Anyway, I thought I'd try this as all the water to oil cooling hoses are the originals and the standard reinforced silicon stuff ain't man enough for that bendy action.

Spent a good few hours getting all Fort Knox ish with my little rotorcave. Well, you can't make it too easy for the local miscreants. So there's a combination of internal and external locking devices along with alarmed padlocks. The internal locks took the most time. Mounting up was easy but getting everything lined up was tedious, especially when everything changes as I tightened stuff down

I lost count of how many times the locks were mounted and unmounted

The final bit to that is the escutcheon plate which gets rivited on. Cue cheap EBay tastic hand riveter that jams on first use so now it needs to come apart. Easy to get apart ... spring under pressure is releaed in pinball type action between garage floor and ceiling. Trajectory tracking was unsucessful ... search and rescue takes almost 30 minutes.

Other components are helpfully scattered randomly on the floor. There are only six components and two possible fitting sequences plus a spring to keep under pressure. I am a legend at re assembling hand riveters now

New skill # 371

Had planned some car time as well but it never happened

More tomorrow ... two sleeps til the motor drops in